Insight into our projects

We intelligently connect what belongs together!

Here you will find a selection of references from our realized projects in the field of energy management – from e-mobility to applications in the commercial and industrial environment.

Our solutions ensure measurable efficiency, sustainable energy flows and intelligent networking.

MultipleX for charging hubs | e-vehicle manufacturers

Turnkey power unit for intelligent energy projects

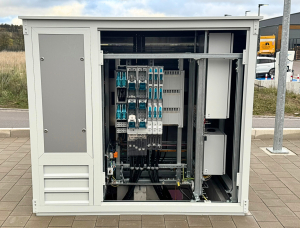

As part of two joint projects with KACO new energy Gmbh, the modular and ready-to-connect MultipleX Power Unit was implemented as a turnkey system solution for two charging hubs in Middle Franconia. These projects are examples of how power electronics, energy management and grid technology can be combined to form an intelligent and powerful overall system.

Find out more!

The MultipleX Unit integrates all central components, from inverters and energy management to communication and protection technology, in a fully preconfigured, modular unit. It is delivered on a prefabricated concrete foundation and is specially designed for direct outdoor installation in the ground. This enables the system to be set up quickly and smoothly, installed efficiently and integrated securely into the grid while maintaining a high level of operational reliability.

Dynamic reactive power provision in accordance with VDE-AR-N 4110 as a central functional feature

KACO Siemens inverters continuously provide reactive power at the grid connection point to actively support voltage and grid stability. The integrated EMS takes over the precise control and ensures that all requirements in accordance with VDE-AR-N 4110 are reliably met.

The system is also directly connected to the grid operator’s telecontrol system, which enables seamless communication with the control center. Remote commissioning, real-time monitoring and comprehensive remote maintenance functions ensure continuous support, analysis and operational optimization.

Clear advantages of the MultipleX solution:

- Complete solution for battery blocks and battery storage systems All in one

- Ready-to-connect power unit incl. Inverter

- Combination of electrical engineering and EMS

- Modular, flexible design

- IoT connection, remote maintenance, AI-supported optimization and trading connection

- Diverse use cases for C&I battery storage projects incl. monitoring

- Quick and easy installation and commissioning

The result:

A powerful, scalable and ready-to-use energy management system that combines grid-supporting functions with high technical flexibility and is optimally designed for demanding applications such as modern charging hubs.

Project insight

Hybrid energy systems with direct marketing | PV open space incl. BESS system

Locations: Grünhainichen, Marbach and Grünberg

At the Grünhainichen, Grünberg and Marbach sites, high-performance hybrid energy systems consisting of photovoltaics and battery storage were implemented. The systems are each connected to the grid operator and a direct marketer and enable market price-based operation while adhering to strict grid connection limits.

Find out more!

In Grünhainichen and Marbach, battery storage systems with a capacity of 3.6 MW each will be used, supplemented by PV systems with 3.18 MWp and 4.2 MWp respectively. The Grünberg site is designed with a battery capacity of 9.6 MW and a PV generator capacity of around 11 MWp. The respective feed-in power at the grid connection point is clearly limited and is actively monitored and regulated by the energy management system.

Based on the current electricity prices, the direct marketer decides whether to feed energy into the grid or, in the event of negative prices, to charge the battery. The energy management system ensures that the specified grid limits are adhered to at all times and prioritizes the use of PV generation. Surplus energy is efficiently stored temporarily and made available to the grid or market as required.

A key technical feature of the systems is the DC-coupled system architecture. By using DC/DC converters, the energy is only converted to AC once. Compared to conventional AC-coupled systems, in which PV and battery are converted several times, this reduces conversion losses and noticeably increases the overall efficiency of the system.

The projects show how large PV storage systems can be operated economically, grid-compliant and market-optimized, with high efficiency, clear power limitation and maximum flexibility in energy trading.

Project insight

C&I application | Gardening and landscaping company

Intelligent EMS with self-consumption and feed-in limitation

An integrated energy system consisting of photovoltaics, battery storage and charging infrastructure was implemented for a gardening and landscaping company. The aim was to maximize self-consumption while simultaneously integrating e-mobility and clearly defined grid transfers.

Find out more!

The system comprises a PV output of 360 kW with inverters from KACO new energya battery storage system with 180 kW capacity from POWEROAD ENERGY STORAGE and a charging infrastructure with a total charging capacity of 264 kW. Six charging columns were installed, each with two charging points from Mennekes Elektrotechnik GmbH. The feed into the grid is limited to a maximum of 30 kW.

The energy management system centrally controls PV generation, storage operation and charging processes. Once the battery storage system is fully charged, the PV power is actively regulated to the permissible feed-in limit. This ensures that grid connection requirements are reliably met and the locally generated solar power is used optimally.

The result is a significant reduction in energy costs, a lower load on the grid and a future-proof combination of photovoltaics, battery storage and charging infrastructure.

Project insight

Location Ulm | IVECO Deutschland AG

Efficient charging infrastructure for the e-truck fleet – intelligently controlled

At the Ulm site, our energy management system supports the efficient distribution of energy during the charging processes of the battery-electric IVECO S-eWay tractor units and chassis running out of production. Dynamic load management, integrated 5G communication and targeted cost and peak load management ensure optimum capacity utilization while reducing grid charges and maximizing grid stability.

Find out more!

Brief project overview

- Components used

– 4x 300 kW Alpitronic Hypercharger, 1x 400 kW Alpitronic Hypercharger

– 6x 5G routers - Project requirements EMS

– Cost and peak load management to reduce grid charges

– Intelligent energy management with dynamic load management

– 5G network communication

Project description

As part of the production of battery-electric heavy commercial vehicles, IVECO is focusing on the expansion of a high-performance charging infrastructure at its Ulm site. The aim was to install five Alpitronic hyperchargers, each with two charging points, in order to be able to charge up to ten electric trucks simultaneously. The focus here was on two key challenges: intelligent load management and a reliable communication infrastructure.

The existing grid connection capacity of 2 megawatts represented the upper limit for the entire site, including ongoing factory operations, which consume around 1.5 megawatts on average. To prevent the power grid from being overloaded, a local energy management system (EMS) was implemented to dynamically control the energy flow. It records the current consumption data in real time, distributes the available power according to demand and thus prevents peak loads during simultaneous operation of the charging infrastructure.

Another challenge was connecting the widely distributed charging points. Instead of conventional network cables or unstable Wi-Fi connections, the system relies on high-performance 5G communication.

Each of the five Hyperchargers was equipped with its own 5G router. A sixth router continuously measures the current power consumption at the grid connection point. Remote monitoring and control of the entire system is also carried out via a central gateway.

Thanks to the intelligent combination of load management and 5G networking, IVECO was able to create a future-proof infrastructure that meets the increasing demands of electromobility.

Project outline

IoT Portal

A customized UI solution was implemented to provide visualization of the entire system as well as individual components. This centralized portal enables seamless access to the system data and thus effortless monitoring and management.

The most important advantages of the IoT Portal:

- Real-time data for instant insights

- Dynamic visualizations that reflect the system status and energy flow

- Alarms and notifications for proactive monitoring

- User management with secure accounts and 2FA

- Scalable and flexible for future expansions

- A single access point (all in one solution)

- Fleet management for multiple systems

- Modern design for an outstanding user experience

E-truck charging infrastructure | Bus companies Switzerland

Commissioning in Switzerland: e-truck charging & load management

The first system components were successfully put into operation as part of an e-truck charging project in Switzerland. The aim of the project is the high-performance operation of e-truck charging infrastructure despite limited grid connection power.

Find out more!

An HPC charging station from Autosun Electric Power Plant Co.,Ltd. with two CCS dispensers. Using dynamic load management at the grid connection point, up to 360 kW charging power can be realized with only 120 kW available grid power. This makes optimum use of the existing infrastructure without overloading the grid connection.

The charging infrastructure is fully connected to a CSMS and enables central monitoring and flexible control of the charging processes. The system is designed for heavy-duty operation with two e-trucks, each with battery capacities of around 375 kWh.

Project features at a glance:

- Dynamic load management at the grid connection point

- Control of HPC charging points

- OCPP integration with real-time data

- Efficient and structured commissioning

The project shows how high-performance e-mobility can be reliably implemented in the heavy-duty sector even under restrictive grid conditions.